Frequently Asked Questions

Q: What is the cost of shipping the log package to my building site?

A: When your building site is more than 50 miles from our yard, the home is shipped by common carrier. We are set up to deliver small cabins in Western Montana. The rates vary because of fuel rates, taxes and if the trucking firm can get a back haul to Montana. We recommend that the homeowner check with trucking firms in their area as they may be looking for a back haul to their area from Montana.

Q: Who does the reset of the home and can I do it myself?

A: We bring our crew to do the reset and charge that at an hourly rate basis. Typically it takes less than one day to do a reset. The homeowner is responsible to have a crane available to set the wall sections. We prefer to do the reset to assure the home is set properly and securely. Our workers are experienced and have all the tools necessary. We are more than happy to help finding a crane company in your area that has the adequate crane.

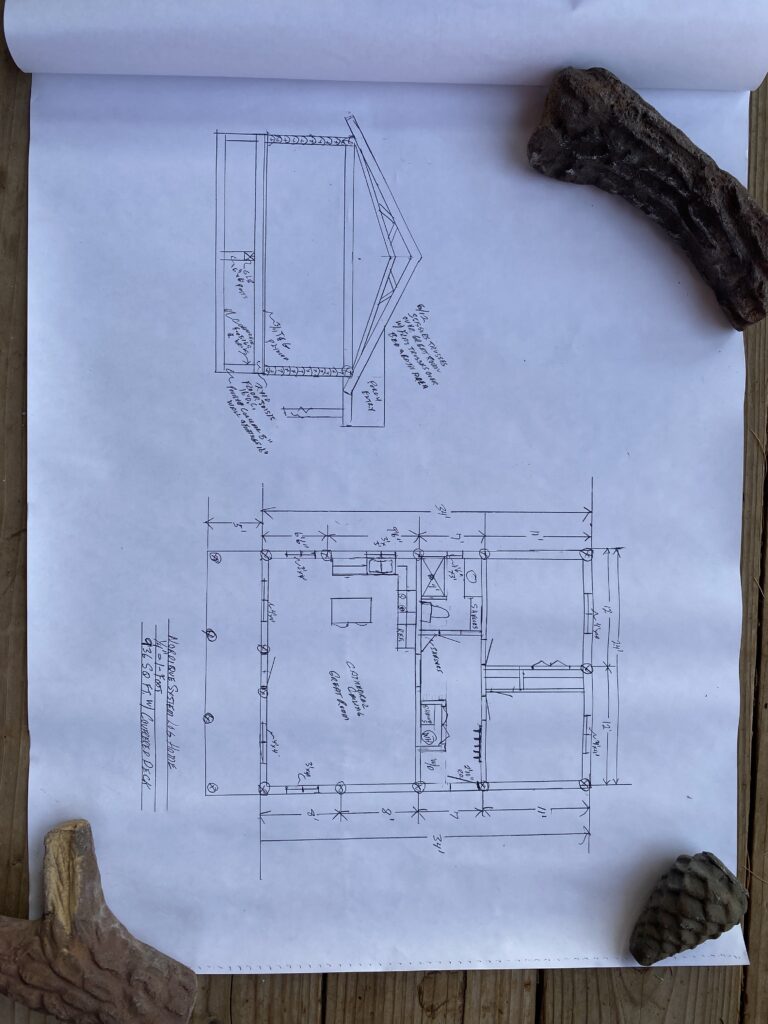

Q: Do you have a plan book or catalog to pick my house from?

A: We custom build all our homes so at this time do not have a limited set of models to choose from. We can help with design, layout and style if you wish. If you have a basic idea of what you desire, a rough sketch is all we need to help develop and estimate the cost of your log package.

Q: How are your horizontal logs fastened to the vertical logs?

A: We start the wall section by using a half log for the first course so it will lie flat on the floor. We then use full logs up to ceiling height. As we are laying out each row, we cut a 3/4 inch wide by 3 inch deep groove in the ends of all the horizontal logs and similar 3/4 inch by 3 inch deep groove in the vertical post. We then insert a 3/4-inch plywood spline that ties the horizontal and vertical together. This is then screwed together and construction adhesive is used to further secure the joint. We use a Swedish cope on all rows with fiberglass insulation between the logs. The rows are then screwed together with hardened steel screws about every 3 to 4 feet and once they are put together, they are never taken apart again to assure a very tight home with absolutely no settling.

Q: What keeps the home from settling?

A: By using the vertical logs on all corners and placing them no farther that 16 feet along the walls, the weight of the roof system is being supported much like wall studs in a frame house. Logs have virtually no shrinkage lengthwise and by securing them to the horizontal logs as described, there is no movement.

Q: Do you have to leave a space above the doors and windows for settling?

A: No, we frame all the door and window bucks in tight and insulate them so there is no chance for air, insect, or rodent infiltration. Since we have eliminated the settling, no space is needed.

Q: Once we have contracted with you to build our log home, how is it paid?

A: We require a 1/3 down payment to start, 1/3 when it is 1/2 done in the yard and the balance when it is done prior to shipping. Shipping and reset costs are paid upon delivery and completion of the reset.

Q: Can I do the foundation, sub floor and finish work?

A: Yes, we can instruct you on some foundation and sub floor details and will work with you or your builder to finish the home. Because of the no settling, any carpenter or homeowner with some basic knowledge of carpentry can complete the home. We will be available to answer any questions you may have through out the process. It is more economical to use local builders as they are familiar with sub contractors, suppliers and building codes.

Q: Do I have to chink my home?

A: Because our logs are hand peeled with draw knives, the variation of cuts will not produce a “furniture fit” joint. We highly recommend chinking but it is not completely necessary. Our homes are built very tight but to reduce the possibility of air and insect infiltration, silicone base chinking is recommended. There are many colors and types of chinking available that are very easy to apply and will last for years. Please feel free to contact us for some recommendations.

Q: What type of finish do I use on the logs?

A: There are many good products on the market today that will preserve and protect your home. We use a lot of a product called Superdeck that is applied with a brush or hand garden sprayer. It is oil base and penetrates very well. We recommend a coat when the reset is done, one more one year later and then re-coat in 3 to 5 years depending on sun exposure. We do not recommend a product that builds up like a varnish but rather something that penetrates and preserves. Check with your local paint store for products that work best in your area.

Q: Will you do a “turnkey” home for me?

A: We have done several “turnkey” homes but they are close to our area. It is usually more economical to use local builders rather than put our crew in motels and the additional costs related to working away from home. If you would like us to put the roof on and install window’s and doors, let us know and we can work out something that will get your home “dried in.” If you need help finding a qualified builder in your area, please contact us and we can be of assistance as we have used builders from many parts of the country. Keep in mind, however, that because of no settling, any builder can do the job.

Q: What type of logs do you use?

A: We use primarily lodge pole pine that has been dead standing on the stump for at least two years. We have found our customers like the “character” marks and consistency in size that lodge pole affords. We do have access to other types of logs so please contact us if you have a specific preference.

Q: What roof system can I use with my log home?

A: With our system of building, you can use any system that can be used with a frame house. We can cut log ridge poles, purlins or any accent logs you wish. Some people prefer a glue-laminated beam or structural trusses, which work very well with our system.

Q: Are you logs milled?

A: No, we hand peel all the logs in our yard. It is a more labor intensive, but we feel it well worth it when the end product is a beautiful hand hewn home.

Q: If I want a garage on my home, is the cost the same as the house shell?

A: We have found it to be more economical to build a frame garage, then put log slabs on the outside. We cut the slabs from the same logs as the house logs so the look is exactly the same and you then have a smooth interior garage wall for storage and tool hanging.

Q: How long does it take from the time that I make the initial deposit until delivery of the shell?

A: For most homes of average size, (1,200 square foot), the time is about 45 working days from the time we start. We work on a first come, first serve basis and presently have the capacity to have 2 homes under construction at a time. Complicated angles, loft logs, roof systems and custom trusses do take a bit longer.

Q: How long have you been in business?

A: We developed our first proto type of the Nordique System in 1996 with the construction of a small “bunk house”. We let it stand for about a year then, after noticing no settling, we constructed a 1,500 square foot home and monitored it though 1997/98 where we had six feet of snow on the roof and still there was no measurable settling. Prior to 1996, 2 of the owners had built several typical “saddle notch” homes and just compensated for the settling like most log home companies do. We did research on possible ways to improve the structural integrity while focusing on ways to reduce cost with “in yard” construction and “on site” completion and concluded that our goal could be reached by changing the load points while streamlining the shipping and reset portion. The result was a product that we patented and have continued, with minor changes, a building system that is currently on the leading edge of log home construction.

Q: You have a patent on this system, what does that do for me?

A: After 2 1/2 years of working with our patent attorney, Mara E. Liepa of Merchant & Gould of Minneapolis, Minnesota and the U.S. Patent we were granted a full patent on our system of building. We are now in a position to set up dealers in other states and contract with builders in your area to provide immediate customer service at a very cost-effective rate.

Q: I have heard that it is difficult to attach fireplaces to a log home, is that a problem with your homes?

A: With a Nordique System Log Home it is not a problem because our homes do not settle or move while the fireplace sits firmly on a foundation. Additionally, stair landings, kitchen cabinets and interior trim does not have to be adjusted for settling.

Q: If I want to use sheet rock and wallpaper on interior walls, can I?

A: Yes, we frame the interior walls exactly like a frame house and cut a saw kerf along the framing member where it attaches to the exterior wall. The sheet rockers just slide the rock into the saw kerf and hang the rack as they would in a frame house. If you desire log interior walls, once again, we use log slabs on frame walls so they are easy to wire for electricity and plumb.

Q: Do I have to scribe along the logs where the ceiling and floor meet the walls?

A: No, we lay a 1 X 6 on the sub floor then the log walls are set on that so there is a space for the flooring material to slide under. We do the same on the top of the cap log so the ceiling material can slip over the log and can be either trimmed or calked.

Q: When you deliver a shell, what is included?

A: In addition to the log walls, we install all the window and door bucks and pre drill for electrical as per your plans. We also deliver all other log materials including log ridges, loft logs, slabs, porch logs and accent logs.

Q: How do I or my electrician wire my home for electrical in the logs?

A: We pre drill for electrical outlets as we are building the rows of logs in our yard and mark where the holes are on the log so all the electrician has to do is drill a horizontal hole on the mark, cut in the box and feed the wire through from under the sub floor. The light switches can be wired along the door jams for a very neat installation.

Q: Do the vertical logs set on the floor joist and sub floor or are they supported?

A: They are supported by a 6 inch by 6 inch “squash block” timber placed vertically from the top of the foundation to the bottom of the sub floor. This transfers the bulk of the weight of the home directly to the foundation and not just on framing members.

Q: How do you keep the gables from collapsing?

A: Once the cap log (the full length log that ties all the sections together) is set, a frame wall is built and sheeted with plywood and log slabs are fastened to this. This procedure will accommodate windows of all shapes and sizes and can be insulated.

Q: If I travel to Montana to visit your log yard, can I see some completed homes?

A: Yes, we strongly encourage you to visit our log yard and we can show you some completed homes and thoroughly go into as much detail as you wish about our building system. Bring your camera as the Swan Valley is beautiful with lots of wild game and beautiful sights to see.

Q: Where do I fly into to get to your log yard?

A: Missoula has the most flights per day but Kalispell is about the same distance. We are located about 80 miles from both Missoula and Kalispell at the 46.5 mile marker on Highway 83 in the Swan Valley.

Q: What are your office hours?

A: Our office hours are 8:00 A.M. to 5:00 P.M., Monday through Friday. The 2 owners of the company live just a few miles from the log yard and are available at any time. If you want to see our operation on a week end, please let us know.